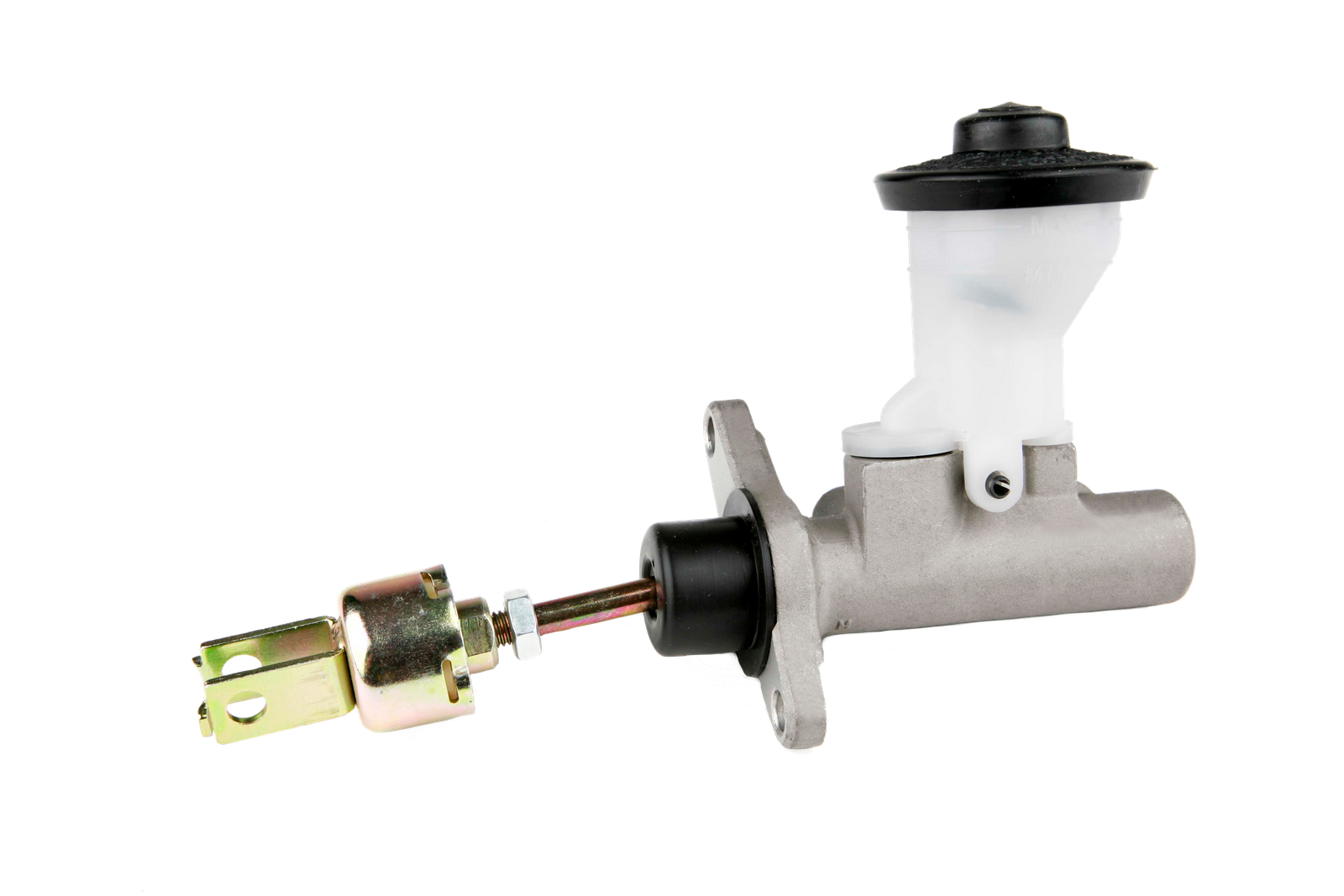

BRAKE & CLUTCH HYDRAULICS

Brake Master and Brake Wheel Cylinders

It is imperative for every vehicle to have a good braking system. PREMIUM PARTS brake master cylinders utilize only high quality cast iron and aluminum. Every component is line-tested to meet international safety standards, providing dependable performance and uncompromised comfort.

Cylinder Body Material Variation

Cast iron

Hard anodized aluminium

Aluminum extrusion

Piston

Aluminum with alumite coating

Rubber Cups and Seals

Advanced technology EPDM and SBR material coating

Advantages of the PREMIUM PARTS Brake Master and Brake Wheel Cylinders:

High corrosion resistance

Vehicle-specific design

High quality rubber components

Mold lip cut design cup

O.E. quality controlled standards

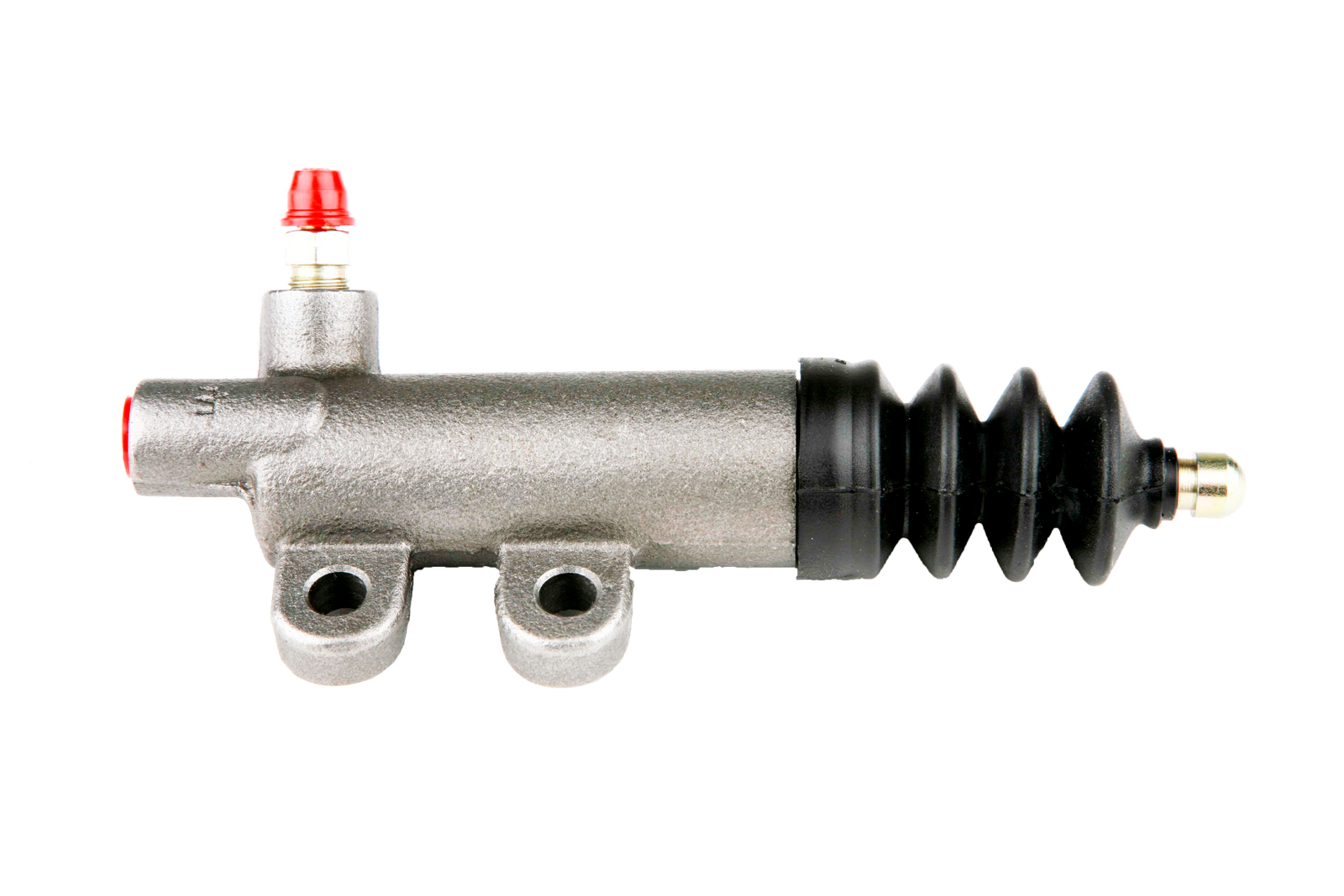

Quality Assurance (Brake Cylinders)

Performace & functional test (SAE J1153/4)

Max pressure test

Pressure build up test

Stroke test

Endurance test (ISO 4928 equivalent to SAE J 1601)

@+120°C

1000 sycle/hr for 70 hrs at 7Mpa

@-40°C

3.5Mpa for 120 hrs